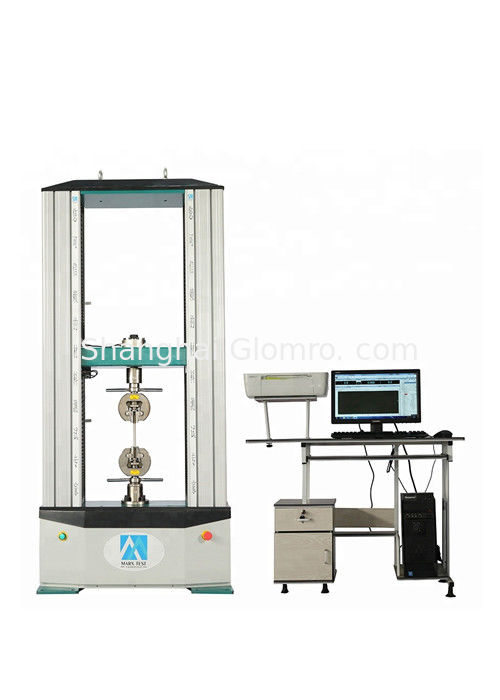

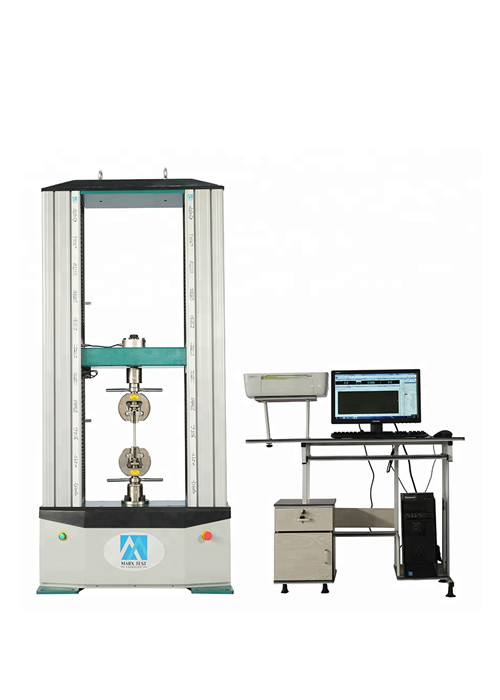

Electronic Tensile Testing Machine

Microcomputer control electronic universal testing machine (floor type)

The main purpose:

This machine can test and analyze mechanical properties of metals, non-metals and composite materials, and is widely used in aerospace, petrochemical, machinery manufacturing, plastics and rubber, ceramic building materials, metal materials, construction engineering and other industries, as well as universities and colleges. Scientific research institutions, technical supervision, quality inspection stations and other departments. It can be stretched, compressed, bent, sheared and tested according to GB/ISO/ASTM/JIS/DIN standards. It can test the yield strength, tensile (pressure, bending) strength, elongation, non-material of materials. Proportional strength, elastic modulus and other parameters.

Host structure

The machine adopts a double-space floor-standing structure, the upper space is stretched, and the lower space is compressed and bent. The main part is composed of four columns, upper beam, middle beam and table. The speed control system is installed in the lower part of the workbench. The Japanese Panasonic AC servo motor with high speed regulation, wide range and stable performance passes the synchronous toothed belt. The deceleration system drives the ball screw to rotate, and the ball screw pair drives the middle beam to drive the stretching attachment (or compression and bending attachment) to move up and down to realize the loading and unloading of the sample. The structure has high rigidity, high efficiency, and stable transmission. The main components of the mainframe are processed in the machining center to ensure the accuracy of the mainframe.

Standard configuration

Wedge stretch attachment, compression attachment, and bending attachment

testing platform

This machine adopts brand computer as the hardware platform, and uses the computer PCI (using plug-and-play PNP technology) slot to directly connect with the test machine acquisition control system to tell, accurately and real-time collect and process data. The measurement and control software uses WINDOWS operating system as the platform, interface Gentle, intuitive, hierarchical, and easy to operate. The measurement and control software can meet the test and test of different materials. The physical properties of various materials can be tested according to relevant international standards, national standards or industry standards, and the user's ideal report can be output.

Test force measurement:

Load measurement: 0.02% FS high stability, high precision imported spoke load sensor with high performance measurement amplification system to ensure high resolution of test force. Multiple sensors can be configured according to user requirements, enabling a wide range of test force measurements.

Sample deformation measurement: 24-bit A/D conversion MCU acquisition system is used, and the deformation of the sample is measured by computer data processing.

Displacement measurement: 2000P/R high-precision imported photoelectric encoder and coaxial screw are rotated coaxially, and the relative displacement of the upper and lower chucks is measured by digital circuit multiplication shaping.

Test force control system

The imported all-digital AC servo controller is used to control the high-performance AC servo motor to drive the synchronous toothed belt, which drives two pairs of precision screw drives with high precision and no gap. It has stable loading, low speed performance, no gap, high transmission efficiency and low noise.

The advantages of smooth transmission.

Convenient operation

The specific six buttons on the external host controller are fast up, fast down, slow up, slow down, start, and clear.

protective device

According to different test positions, the position of the limit switch can be adjusted to effectively prevent the clamp from colliding.

It has protection functions such as overload, overcurrent and leakage.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!