Switch on the power, start the motor. Using an oilstone stained with ordinary lubricants completely polished shaft sleeve, press evenly oilstone with your thumb when polished,wipe motor shaft sleeve after polished, stop the motor. The purpose of polished is to eliminate the impact of original film or nanometer film on the experimental results.

1. Fix the friction block into the short lever groove of the testing machine,add ordinary lubricant oil into oil box, well-installed the lubricating oil box and the length of the lever.

2. Start the motor, firstly, let the motor run.Then at set intervals (such as 10 seconds), plus the weight on long lever ends one by one, each weight is equal to the pressure of the friction pair carrying 100 kg. Record the number of weights, look at change in ammeter pointer, the pointer increase, power consumption increase, fuel consumption also increase. Noise increases, continue to add weight (about 3,4 blocks) until the wheel stops, the machine locking, quickly turn off the power. Remove the weights, remove the short lever, observe the depth, area and roughness of grinding marks on cylindrical grinding block.

3. Choose a different angle on the grinding block to install leverage. Polish shaft sleeve again,it need to polished flat because the wear in just experiment .

4. Add our wear-resistant lubricating oil into oil box.

5. Plus the weight on long lever ends one by one, one, two ...... Ordinary oil plus about four, the machine will be locked, but our wear-resistant lubricants plus more than four, the machine still operate as usual. Look ammeter pointer, only slightly move a little. Current × voltage = power consumption, ammeter pointer changes very little,power saving is fuel saving. Gradually add weight to 12, the machines also operate as usual

6. Remove the oil box, the machine operate as usual. Nano films do exist, turn off the machine switch.

7. Put down the grinding block to compare with previous grinding marks.

(The testing machine equipped with our infrared thermometer can make oil temperature experiment: The steps are: put the grinding block horizontally, plus three weights on the long pole, heat the oil to boiling, note the time from the start heating to boiling , the longer of the time, the better quality of the oil.)

Every time change the oil must use an oilstone stained with ordinary lubricants to polish shaft sleeve clean.If not clean, the machine will shake and accompanied by noise, affect experimental results.

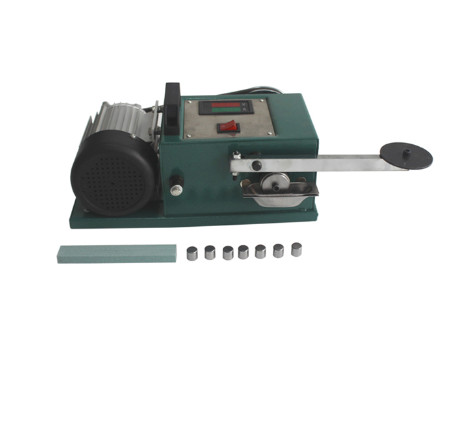

Packing List

| Machine body |

wear-resistant tester 1 set |

| Weight |

12 piece |

| Oil cup |

2 set |

| Oilstone |

2 piece |

| Power cable |

1 piece |

| Grinding block |

30 piece |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!