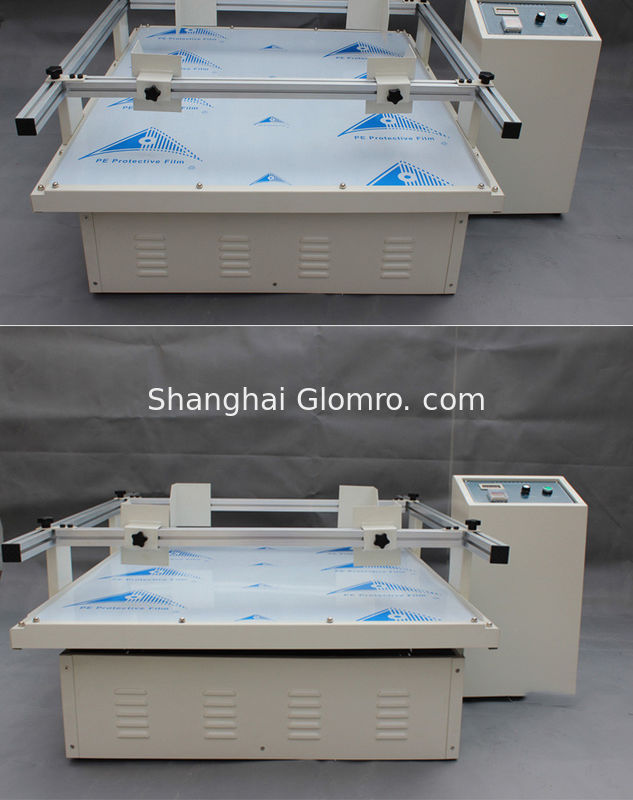

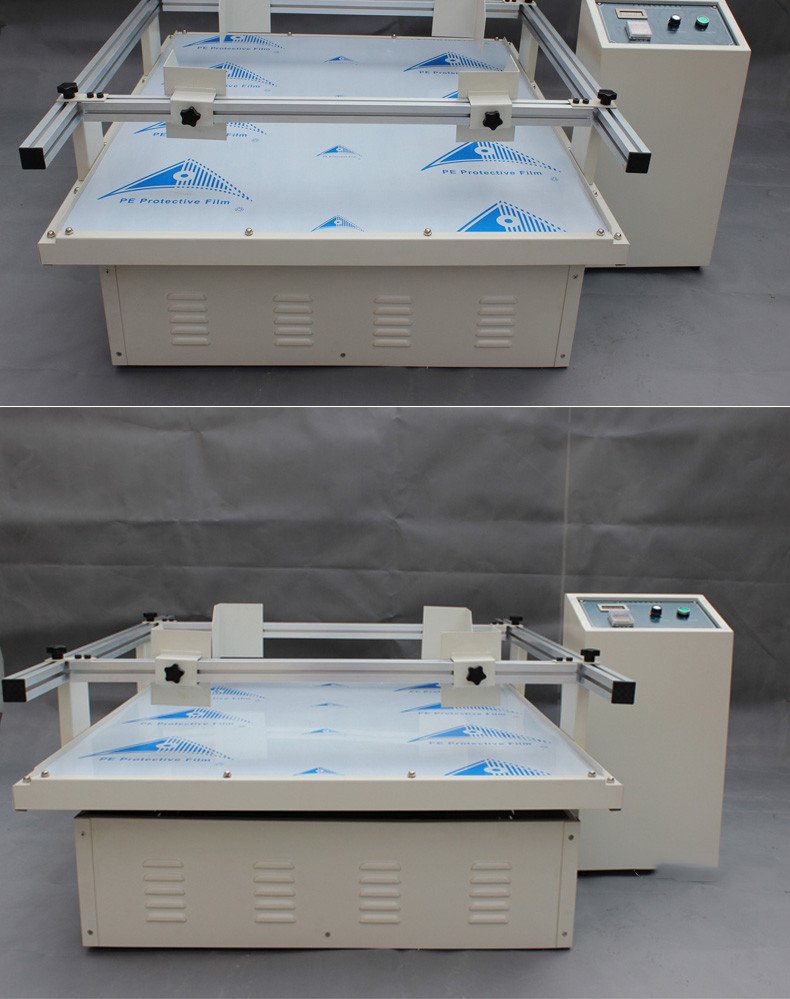

Analog Type Transportation Vibration Simulation Packaging Box Vibration Test Equipment/Package Vibration Simulator

Summary:

Vibration Testing Machine is used to test the anti-vibration capabilities of large pieces of furniture, household appliances, office furniture and other large objects, as well as the simulated transport vibration test of the packaged products, to assess the degree of vibration-resistance.

Vibration Testing Machine which simulates a transporation environment, is applicable to the vibration test of toys, electronics, furnitures, gifts, ceramics, communications, packagings, equipment, computer and automobile components, etc.

characteristics:

1. Smooth operation, low noise. Suitable for office and the laboratory installation.

2. The unique slippery course structure design, make sample clamping conveniently and reliable.

3. Timer fuction is elegent appearance.

Features :

- 1.Porgrammble design,the frequency ,vibration time can be set

- 2. Vertical & Horizontal vibrate

- 3. Color touch screen easy for ovperation

- 4. Max. Load up to 70kg suitable for elcetronic parts and others products.

Equipment Overview

Vibration Simulation Testing Machine / Transportation Vibrating Table, also called the shaking table, is used to simulate the bump damage to the product during the transportation, so as to identify whether the product can endure the environmental vibration. It is suitable for electronics, electromechanical, , steam locomotives and toys. Research, development, product management and manufacturing in all walks of life. It is the most reliable test machine for improving the quality of your products.

Quick Details

Place of Origin:

Shanghai, China (Mainland)

Brand Name:

GLOMRO

Model Number:

GLO-5024

Power:

Electronic

Frequency accuracy:

1rpm

Packaging & Delivery

Selling Units:

Single item

Single package size:

120X108X60 cm

Single gross weight:

150.0 kg

Lead Time :

| Quantity(Set) |

1 - 10 |

>10 |

| Est. Time(days) |

7 |

To be negotiated |

Product Description

Application:

transport simulation vibration testing equipment price is used for simulating the destruction of the vibration of all kinds of packaging items, PC board, electric appliances etc. during the transportation, test results can be used as reference for design packaging.

Specification:

| Model |

GLO-5024 |

| Vibration frequency |

100-300rpm |

| Frequency Precision |

2rpm |

| Load Capacity |

100kg |

| Displacement |

25.4mm |

| Standard Motions |

Rotary DC Motion (Standard) |

| Standard Table Size |

1200x1000 mm |

| Timing functions |

99H99M |

| Dimensions |

120*108*60 cm (LxWxH) |

| Weight |

150kg |

Features:

1. Vibration frequency digital display, high precision;

2. synchronous mute broadband transmission, low noise;

3. sample fixture with rail, easy to operate and safe;

4. Heavy-duty channel base with vibration-damping rubber, easy to install, strong load, stable operation;

5. According to the restructuring of similar equipment in Europe and America, rotary vibration, in line with European and American transport norms;

6. Suitable for toys, electronics, furniture, gifts, ceramics, packaging and transportation industry to test the packaging of products;

7. According to the restructuring of similar equipment in Europe and America, rotary vibration, in line with European and American transport standards.

Note: When moving the machine can not lift the aluminum around to prevent bending deformation

Operation method:

1. The test product is placed shaker center;

2. Use a wrench to loosen the nut on the positioning bar

3. With both hands patted the mobile, the test product is fixed with a fixture, tighten the nut;

4. Check if the equipment collides with other objects (this equipment must have a space of 0.5m to 1m around it);

5. Regulator accelerates from left to right, (Note: the minimum speed of not less than 100 rpm, the maximum speed does not exceed 300 rpm;

9. After the test is completed, press the "STOP" key (red light is on), then the motor is powered off and the test data is removed and recorded;

10. Press the "POWER" switch to turn off the power.

Main Features

1. Vibration frequency digital display,

2. Synchronous silent broadband transmission, low noise

3. The sample clamp adopts the guide type, and the operation is convenient and safe

4. Heavy channel steel base with damping rubber, easy to install, strong load, smooth operation

5. According to the similar equipment reform in Europe and America, the rotary vibration is in line with the transportation norms of Europe and America

Installation Requirements

1. The distance from the adjacent wall or other machine body is greater than 60cm.

2. To stabilize the play to the performance of the machine, should choose the temperature of 15 °C ~ 30 °C, relative humidity is not more than than 85% of the venues.

3. Should be installed on the level ground (application level is confirmed on the ground).

4. Should be installed in the place without direct sunlight.

5. Should be installed away from combustibles, explosives and hot and hot sources, so as to avoid fire.

6. The testing machine shell must be grounded reliably, otherwise there is electric shock hazard.

7. When the machine is running, do not touch the outside of the control panel with your hands to prevent chafing or injury.

8. If you need to move the machine, be sure to cool off for 5 minutes after cutting off the power.

Maintenance Instructions

1. After each use of equipment, the cleaning work should be done inside and outside the equipment;

2. The spray coating of the equipment should be used regularly to protect against corrosion and anti-rust oil on the outer surface of the equipment;

3. The test machine is used for a long time. It should be lubricated regularly in the driving part of the machine. The motor needs to be checked and cleaned regularly. No dust can be accumulated in the motor housing;

4. The normal operation of motor, the motor in operation, such as a special ring, the surface temperature anomalies (temperature greater than 70 °C), it is necessary to stop the machine immediately to check, if the bearing damage, should change in Time; If the lubricant is lacking, If the lubricant is lacking, use the calcium sodium base grease to lubricate;

5. When storing and using equipment, there are no inflammable, explosive and corrosive substances around;

6. The machine is used for operation and maintenance.

Packaging & Shipping

1. Aluminium box and carton box, careful and tight package, make sure the package is intact

2. The package will be shipped by DHL/Fedex/TNT/EMS/UPS/China post/EF-Express/Special line, as you have chose in the order.

Our Services

If you encounter with any problems during the testing process,we promise providing urgent guidence and after-sales sevice within 48 hours and solution providing within 3 working days. If customers require on-site service, the transport and travel expense shall be responsible for the cost.

1. Pre-service

24 Hours online service for customers' consultation.

2. Middle service

-- Fullfill customer's request:

-- Payment method depends on customer.

-- Promptly production and delivery

-- Can provide invoice value if you want to decrease your tax.

3. After sale service

-- One year warranty service and all life maintenance.

-- Technical Egineer are avalible for oversea trainning.

-- Remote control technical consult

Company Information

Shanghai Glomro Industrial Co., Ltd was founded in 2012. Specializing in the production of testing equipment and industrial measurements and instruments products. Products of high quality, fashionable, widely used in a variety of industrial areas, not only has the broad masses of the domestic sales market, but also exported to Europe and the United States.

Glomro hinge over the years has always adhered to "quality of products in order to survive, credibility and development services" business purposes. Committed to providing you with high-quality products and quality services. Have a professional, dedicated design management team, from product design, mold making, molding to the Product assembly, for each aspect and processes are rigorously testing and control.

Over the past few years of production and management and exploration, Longtai set up its own quality management system. Industry standards including SAE,IEC JEDEC,ASTM and MIL-STD,ISO:9001,UL,CE certified. Glomro always implement the concept of customer value creation for customers tailored products to meet the needs of different customers, and continuously provide customers with solutions to technical problems,further exploration innovation,and excellence.

Warmly welcome you and opening up the boundaries of communication. We synchronize with your ideal partner!

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!