Falling Ball Impact Testing Equipment For Plastic Glass Ceramic And Acrylic

Application:

Drop ball impact test equipment is used to test the plastic, ceramic, acrylic, glass woven and other materials and coatings firmness. This equipment complies with JIS-K6745, A5430 test standards. The machine to a certain weight of steel ball adjusted at a certain height, the ball free fall hit the test sample, depending on the extent of damage, in order to determine the quality of the test product, the device by the vast number of manufacturers praise, is An ideal test equipment.

Product parameters

| Technical specifications |

| Falling height |

0-2000mm adjustable |

| Drop position |

Infrared positioning, the drop point more accurate |

| Falling ball control method |

DC electromagnetic control |

| Ball weight |

55 64 110 255 535G |

| Power |

220V, 50HZ, 2A |

| Machine size |

50 * 50 * 220cm |

| Machine weight |

about 25kg |

The drop ball impact tester is suitable for testing the impact strength of plastics, ceramics, acrylic, glass, lenses, hardware and other products.

The machine will test the product on the test bench, the ball of specified weight will fall freely on the product from the specified drop height, impact the product, and then check the appearance of the product and all aspects of performance. The device is designed according to the "6.10 Shock Peeling Performance Method" of "GB/T9962-1998 Building Safety Glass Material-Safety Glass Performance Specification and Test Method", and meets the impact test requirements of building safety sandwich. Reliability test standards: JISR3205:1989, ISO/DIS12542112543-6:1997 AS/NZS2208:1996, GB/T9962-1999.

technical parameter

1. Ball Weight: 55, 64g, 110, 225, 535g (Remarks on Choosing a Ball Ordering) can be purchased according to requirements.

2. Allowable error of steel ball weight: +5g

3. Protective device: there are protective net boxes around it.

4. Control and lifting mode: Circuit control electromagnet chuck, manual lifting electromagnet fixed rod

5. Drop height: 0-1500/2000mm (2m customized)

(Manual adjustable, steel ruler display scale, selected according to requirements)

6. Display of drop height: vertical indication of scale steel ruler plus right angle ruler

7. Precision of drop height: 1mm

8. Dropping rod shape: square rod

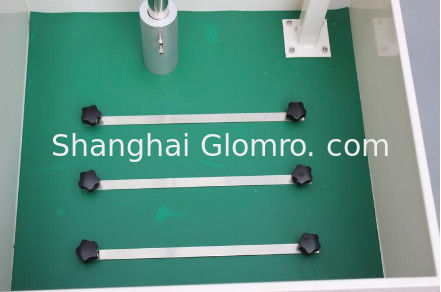

9. Sample Frame Workspace: 400 x 350 mm

10. Sample clamping method: clamping fixture

11. Dropping iron plate: thickness 10 mm

12. Machine Size (L X W X H): About 500 X 400 X 1800 mm

13. Machine weight: 30kg

14. Working power supply: AC220V, 50HZ

Operational instructions

1. Hold the sample, according to the shape of the sample and the drop of the customer, use universal fixture to clamp the sample (whether the sample needs fixture clamping according to the customer).

2. Start setting the test schedule, unscrew the fixed handle on the electromagnet pole with the left hand, move the bottom end of the electromagnet fixed pole to 4 cm above the required drop height (the drop height is not very precise at this time), then tighten the fixed handle slightly, and attract the steel balls needed to the electromagnet. One end of the right-angle ruler is perpendicular to the scale of the height required on the drop rod. By slight movement, the lower end of the steel ball is perpendicular to the scale of the height ruler of the required height, and then the fixed handle is tightened.

3. Start the test, press the drop key, the steel ball falls freely, impact the test product, repeat the test and replace the steel ball test or replace the product test according to the customer's needs, at this time should record the test results of each time.

4 Notes and Maintenance

1. Align the center of the steel ball to the center of the fixture and fix it well.

2. When the steel ball falls down, it may jump out of the box, so we should pay attention to safety.

3. Do not scratch the surface of the machine with sharp tools.

4. Clean the machine after each test.

5. Wipe the steel ball clean and put it back in the box.

6. After the test, please turn off the power supply.

Packaging & Shipping

1.Aluminium box and carton box, careful and tight package, make sure the package is intact

2. The package will be shipped by DHL/Fedex/TNT/EMS/UPS/China post/EF-Express/Special line, as you have chose in the order.

Our Services

If you encounter with any problems during the testing process,we promise providing urgent guidence and after-sales sevice within 48 hours and solution providing within 3 working days. If customers require on-site service, the transport and travel expense shall be responsible for the cost.

1. Pre-service

24 Hours online service for customers' consultation.

2. Middle service

--Fullfill customer's request:

--Payment method depends on customer.

--Promptly production and delivery

--Can provide invoice value if you want to decrease your tax.

3. After sale service

--One year warranty service and all life maintenance.

--Technical Egineer are avalible for oversea trainning.

--Remote control technical consult

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!